Product Category

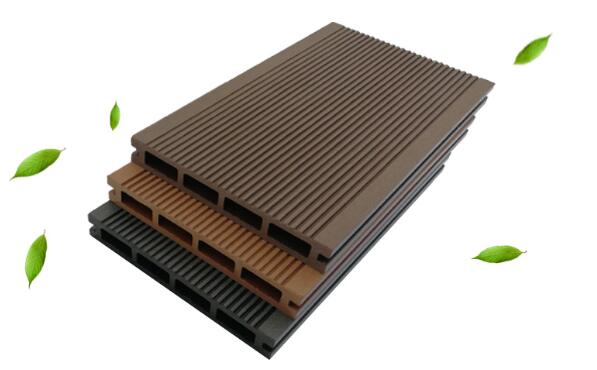

- Composite decking (WPC )

- DIY interlocking decking tiles

- Wall Panel(composite Siding)

- WPC | Composite Fencing

- WPC | Composite Railing

- WPC Bench

- WPC dustbin

- WPC Flower Box

- WPC Pergola|Pavillion

- WPC Table

Contact Us

Salesman Name: Nick ,Jean,wendy,Alex

Tel:+86-572-6725956

whatsapp:0086 18705825615

wechat:3402182830

Skype:Nickwpc88

Email: Admin@hanmingwpc.com

Add:Huzhou City, Zhejiang, CHINA

Follow Us:

- Outdoor WPC decking

Hanming WPC Pergola

Garden WPC Decking

WPC Fence

Stainless steel park bench

WPC Flower BOX

Hanming WPC dustbin

Pontoon composite wood

Terrace WPC decking

Assemble flower box

Pergola made of WPC

Outdoor WPC Signage

News

-

How to cut wpc composite decking boards ?

We know Plastic wood composite decking can be cut by using ordinary woodworking machinery.When wood plastic products are cut or drilled,Alloy saw blades and bits are recommended,because More convenient and flexible in cutting. in Factory, we Cut single pieces to length using any standard Profile cutting machine,The saw blade must be sharp. we can cut the wpc board to be 2.2m/PC, 2.9m/pc,3m/pc,5.4m/PC.etc. Choosing the best saw blade for your composite deck build can help you save time and money. when we install the composite decking board , we need a Portable cutting machine. WPC decking is a pressed extruded composite wood product made from wood powder and recycled plastic. Although it is an unconventional deck, it can be cut, drilled and fixed like traditional wood. Cutting can generally be done by using standard woodworking tools. Table saws, circular saws, and miter saws are your best choice. Choose the blades made of a hard alloy to ensure a smooth cut. Be careful not to overheat the blade during cutting, otherwise, it will affect the cutting effect. Here is a Video for How to cut Trex decking; Plastic wood decking has the same processing performance as the log, it can be nailed, drilled, and cut,WPC decking has a […]

-

A different landscape—Garden WPC Pergola

A yard full of flowers,Green Pergola is indispensable.Plant climbing plants on the column feet, Next spring Green leaves and flowers wrapped around a Pergola in a courtyard would be a different scene.The pergola should be built in a sunny position.It can be designed as a work of art,Because the ornamental effect of grape pergola still should combine the design of courtyard. Plastic wood outdoor materials are more and more used in garden engineering, including the plastic wood Pergola and plastic wood pavilion ,etc.It solved the problem of dull color on the surface of wood,The plastic wood profile surface has rich color simulation wood grain effect, Change the single effect of metal surface,With a natural noble and gorgeous appearance of wood grain in front of the world,Thus enhanced the decoration effect. Plastic wood Pergola has Features of high strength,Easy to process and install.Basically maintained the original advantage of plastic,At the same time, it has a noble and elegant appearance of wood,The surface of plastic wood profile is smooth and can with natural wood grain,Solved the vexation that lumber needs to paint in construction,Can raise construction speed. WPC materials in the process of use,Having the characteristic of being resistant to acid-base corrosion,At the […]

-

Why do We Use Wood Plastic (WPC) Products Instead of Other Materials for outdoor

WPC materials are becoming more and more popular in modern outdoor use, and their unique performance advantages make them an ideal alternative to many traditional materials. Compared with traditional materials such as pure wood, metal and plastic, wpc materials are particularly durable and environmentally friendly. Because wood plastic materials are made of wood powder and plastic, they not only have the appearance of natural wood, but also overcome the shortcomings of pure wood being easy to rot and susceptible to insect pests. In addition, compared with metal materials, wood plastic materials are lighter and less prone to rust, while avoiding the environmental pollution problems that plastics may cause, providing a more sustainable choice. Reasons for choosing wood plastic materials over other materials also include their ease of maintenance and cost-effectiveness. The maintenance requirements of wood plastic materials are much lower than those of wood and metal materials, and no regular oiling or anti-rust treatment is required, which greatly reduces the maintenance cost of long-term use. At the same time, although the initial investment of wood plastic materials may be higher than some traditional materials, their longer service life and lower maintenance costs mean higher cost-effectiveness. These factors together make wood-plastic […]

-

Manufacturing Technology of Wood and plastic products in China

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC, PLA etc.). In addition to wood fiber and plastic, WPCs can even contain different ligno-cellulosic and/or inorganic filler materials. WPCs area unit a set of a bigger class of materials known as natural fibre plastic composites (NFPCs), which can contain no cellulose-based fiber fillers like pulp fibers, peanut hulls, bamboo, straw, digestate, etc. Composite decking may be a semisynthetic building product that has AN approximate equal mixture ofrecycled wood fibers and recycled plastic. as a result of composite decking product area unit thus sturdyand run-resistant to rot, they need a way longer lifetime than wood decks. they are doing not need the staining, sanding, sealing, and board replacement that return in conjunction with wood decks. even if they need a lot of initial investment, a composite deck over makes up for that initial value over the lifetime of the deck. With the numerous blessings of composite decking, like lower maintenance and being immune to mildewand insects, composite decking has been deemed one amongst the most durable decking productson the market nowadays. additionally to those advantages, new capped composite decking is additionally stain and fade resistant, which implies it’s easier to scrub and has terribly high color retention. Maintaining your composite deck requires semi-annual cleaning; simply a fast spray of the hose with a gentle house cleaner can do the trick. Capped composite decking is sealed and is less complicated to scrub if mildew and mildew type on the surface. Since there area unit exposed wood fibers in uncrowned composite decking planks, it may be vulnerable to mildew growth rather like any outside surface. However, improvement your deck sporadically will facilitate keep mildew trapped. Wood-plastic equipment experts introduce the existing technology, wood plastic products including several forms of molding: extrusion molding, calender molding, injection molding, pressing molding […]

-

What is wood plastic ? | where can wood plastic be applied ?

As early as a few decades ago, the United States began the research and extrusion of wood-plastic composites, but due to the immature processing technology, compared with plastics and pure wood products, there are many performance defects, wood plastic composites have not been rapid development. With the breakthrough of industrial technology level, the new processing technology has greatly improved the performance of wood Plastic composite materials, and the market of wood-plastic products has opened rapidly with the breakthrough of industrial technology level. The new processing technology has greatly improved the performance of wood-plastic composites and opened the market of wood-plastic products rapidly. 1:What is wood plastic ? Wood Plastic Composite (WPC) is a new kind of composite material which is flourishing in recent years at home and abroad. It refers to the use of polyethylene, polypropylene and polyvinyl chloride (PVC), instead of the usual resin adhesive, and more than 35% – 70% of wood flour, rice husk, straw and other waste plant fibers mixed into a new wooden material, and then extruded. Molding, injection molding and other plastic processing technology, the production of plates or profiles. At present, mainly used in building materials, furniture, logistics packaging and other industries. It […]