Product Category

- Composite decking (WPC )

- DIY interlocking decking tiles

- Wall Panel(composite Siding)

- WPC | Composite Fencing

- WPC | Composite Railing

- WPC Bench

- WPC dustbin

- WPC Flower Box

- WPC Pergola|Pavillion

- WPC Table

Contact Us

Salesman Name: Nick ,Jean,wendy,Alex

Tel:+86-572-6725956

whatsapp:0086 18705825615

wechat:3402182830

Skype:Nickwpc88

Email: Admin@hanmingwpc.com

Add:Huzhou City, Zhejiang, CHINA

Follow Us:

- Outdoor WPC decking

Hanming WPC Pergola

Garden WPC Decking

WPC Fence

Stainless steel park bench

WPC Flower BOX

Hanming WPC dustbin

Pontoon composite wood

Terrace WPC decking

Assemble flower box

Pergola made of WPC

Outdoor WPC Signage

News

-

Brief introduction and Development Prospect of Plastic-Wood Materials

Wood plastic composite (WPC) is a new kind of green environmental protection composite, and is the ideal substitute for wood. Waste wood and environmental pollution can be reduced. This paper briefly introduces the plastic-wood materials, application fields, advantages and disadvantages, as well as the present situation of application at home and abroad, analyzes the development trend of wood-plastic composites, and confirms the necessity and feasibility of developing wood-plastic composites. [keywords] Plastic-wood material plastic application field keyword] the development prospect 1, the plastic wood material brief introduction “the plastic wood material”, also called “the wood plastic composite material”, As the name implies, it can be understood as mainly using plastics as raw material, through adding wood powder, rice husk, straw and other waste plant fibers to mix into new wood materials, and then through extrusion, molding, injection molding and other plastic processing technology, the production of plates or profiles. Mainly used in building materials, furniture, logistics packaging and other industries. It is called extruded wood-plastic composite board that the plastic and wood powder are mixed in a certain proportion and then hot extruded. The main ingredients of plastic wood are plastics and natural fibers. Compared with the traditional wood, the biggest […]

-

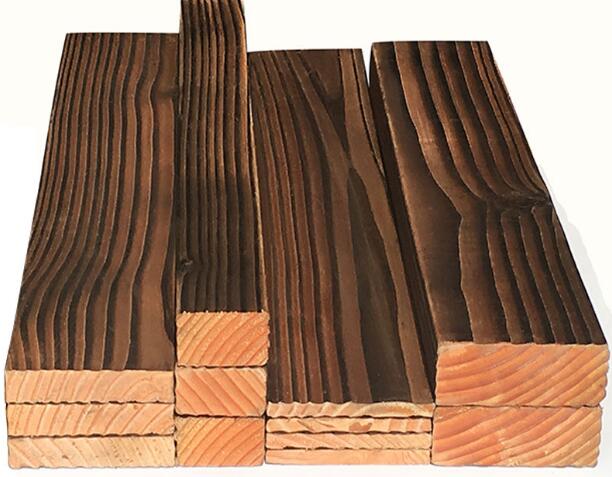

The difference between wpc decking and anticorrosive wood

Let’s first talk about their process, anticorrosive wood is artificially anticorrosive wood, treated wood has the properties of anticorrosion and insect prevention, WPC board, that is, wood plastic composite, It is a new material formed by mixing waste plant raw materials with polyethylene and other chemical adhesives. In view of the many friends often asked about the difference between plastic wood and embalmed wood, today again put out a hot passion to explain the story between plastic wood and embalmed wood again. First, the loss of WPC profile is less than that of anticorrosive wood. Under the condition of the same construction area or volume, the loss of plastic wood is less than that of anticorrosive wood, because plastic wood is a profile material, which can be produced according to the actual size of landscape engineering to meet the needs of length, width and thickness. The length of the preservative wood is prescribed dead, usually 2 meters 3 meters and 4 meters. Second, WPC is the same construction conditions, can be less than more. Let me take an example. For example, in […]

-

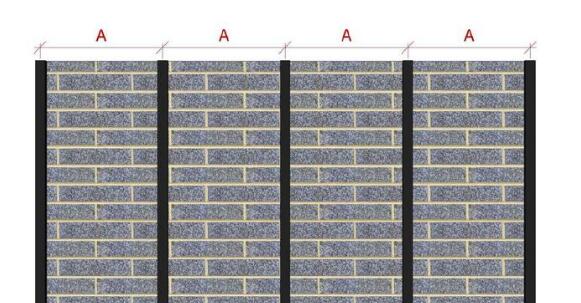

How to install wood plastic composite wallboard ( WPC wall cladding )?

How to install wood plastic composite wallboard ( WPC wall cladding )? Wood-plastic exterior wall board makes the building appear simple and natural and beautiful, can resist all kinds of bad weather, and anti-corrosion and flame-retardant, easy to install. No matter in the production process or in the engineering practice, it can not pollute the environment and can be reused, so it is an ideal decorative material for environmental protection. The plastic-wood composite Siding is light in weight, insulated, moisture-proof, flame-retardant, acid-alkali resistant, corrosion-resistant; stable, good dielectric, durable, anti-aging, easy to weld and bond; strong flexural strength and impact toughness, high elongation when rupture; smooth surface, Bright color, very decorative, wide application of decoration, simple construction technology, easy installation. From the professional consideration of installation, WPC wall cladding is suggested to be installed by professional construction personnel. Please clean the wall before installation and make the wall dry, smooth and clean. If there are construction industry regulations or local regulations, please install them according to the regulations. 1, fixation of keel (as shown in figure) Steel keel is aslo usually used. The space between keels should be less than 400 mm. The steel keel should be fixed on the wall […]

-

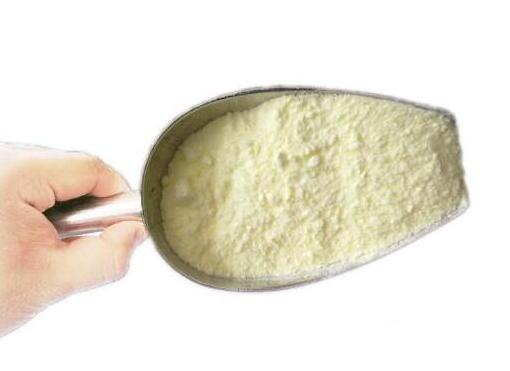

Different additives in the WPC Paving decking | WPC additives

WPC materials have become very popular, but there are few articles about WPC additives. Today, the editor-in-chief will talk about WPC additives. 1, PVC resin. Plastic profiles are usually made of rigid resin with a polymerization degree of 1000 (SG5) and a K value of 66~68. Although the resin supplier’s brand and production process are different, but the general profile manufacturers resin selection is fixed, will not change at will. However, there are batches of unstable factors in the resin produced by acetylene. If the best batch is selected, the same batch should be adopted. Moreover, the colorant is made up of three parts of the carrier, the color agent and the additive. The colorant has some degree of insolubility with the PVC resin. Therefore, when choosing the carrier of the colorant, the coloring agent should be the same type as the resin to be coloured, and vice versa. 2. Stabilizers. Stabilizers have a positive effect on the fastness and weatherability of plastic products. Stabilizers are heat stabilizers and light stabilizers. It is not only to add such additives in the profile formula, but the coloring agent itself is also to be added, and it is best to be consistent […]

-

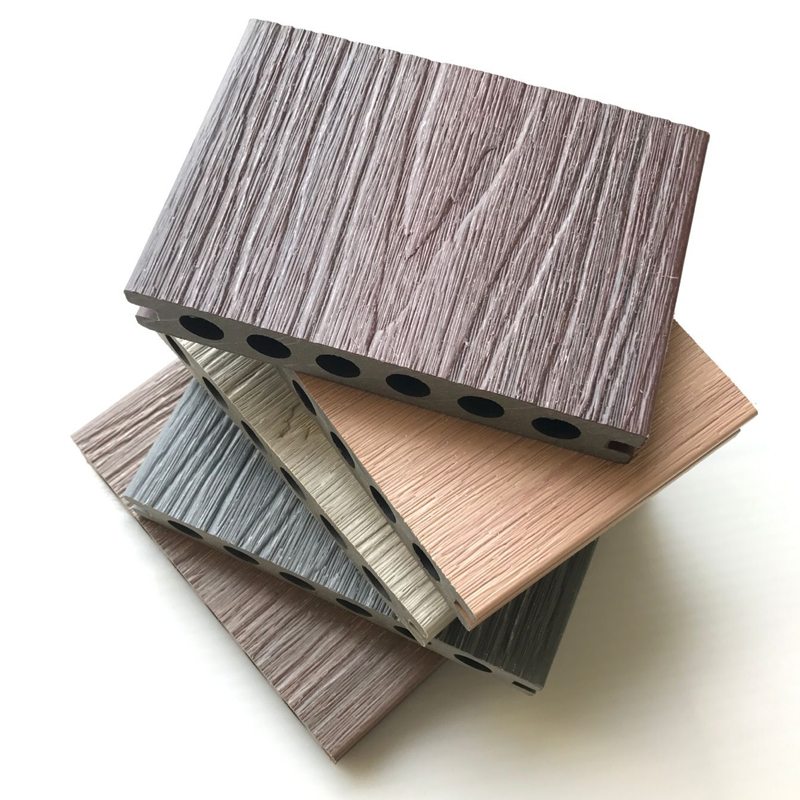

PE WPC Decking VS PVC WPC decking | Is PE decking better than PVC decking ? ABS wpc decking

1, PE WPC decking: Advantage: PE wood-plastic materials have excellent waterproof and corrosion resistance, high hardness, easy to change buckling when heated, but the effect of using thickened or porous hollow structure is good. Reply to “PE” to see more Shortcomings: 1) the limited number of products used for outdoor use is now in use for 3-5 years. 2) The anti-oxidation and anti-light decomposition ability is poor, even if the antioxidant and UV reference agent are added, the effect is not ideal, and will affect the product strength and color fastness. 3) the appearance of the product is pure, with no wood sense and poor appearance. 2, PVC WPC decking: Advantage: 1) PVC wood plastic products can be used new material, also can be made of old material (while PE is too high in cost with new material, the product has no way to enter the market), the modification is also easier, the quantity of the supplementary quantity depends on the quantity of production. 2) PVC can be made into low foamed wood plastic products, which is lower in cost. It is considered suitable for the use of coextrusion (double extrusion or steel plastic extrusion), and the strength and […]