Wood plastic composite decking has been widely used in various fields due to its excellent performance. First of all, in home decoration, it has become the preferred material for many families due to its environmental protection and durability. It is not only beautiful and generous, but also easy to clean and maintain, which brings great convenience to family life. Secondly, commercial spaces such as hotels, restaurants, shopping malls and other places often choose wood plastic composite decking as floor decoration materials in order to create a comfortable and elegant environment. In addition, outdoor facilities such as parks, squares, pedestrian streets and other places often use this material to lay the ground because of its waterproof, moisture-proof and corrosion-resistant characteristics. It is both practical and environmentally friendly. In general, wood plastic composite flooring has shown strong application value in various occasions with its unique advantages.

Let’s understand the basic characteristics of outdoor WPC decking . Outdoor WPC is a composite material that uses high-density polyethylene (HDPE) or polypropylene (PP) and other polymer materials as the base material and is processed through special processes. It has the following salient features: 1.Water resistance: Because its base material has excellent waterproof properties, outdoor wpc Deck can maintain stable physical properties even when exposed to rain and moisture for a long time. 2.Anti-corrosion: Compared with wood, outdoor wpc decking is more resistant to corrosion and will not be damaged by moisture or insects, extending its service life. 3.Easy to maintain: Because its surface is smooth and does not easily absorb dirt, cleaning and maintenance are relatively simple, just rinse with clean water.

We need to know that the material for the production of wood plastic composite decking can be called “ecological wood “, what is called” ecological wood “, because its production process does not contain formaldehyde, nor any material harmful to the human body, both safe and environmentally friendly a composite material. So in the choice of decoration materials now more consumers tend to plastic wood floor. The WPC floor is made of wood and other raw materials into powder and plastic, and then pressed into a model under high temperature conditions, in the production of the product is not required to use adhesive, so it does not contain any harmful substances; but the traditional floor is not the same, like solid wood or composite ground Formaldehyde is a harmful substance to the human body, so the plastic wood floor should be promoted more than the traditional floor.

Outdoor wood polymer composite

Wood lastic composites, as we have said many times before, not only have the characteristics of strong wood sense, but also have the characteristics of anti-corrosion, moisture-proof and moth-proof, its application field is wider than solid wood materials, because of the excellent anti-corrosion and moisture-proof properties of wood-plastic composites, it also has a good application in the outdoor. Because composite decking have both the properties of water-resistant and anti-corrosion properties and the texture of wood, and because the plastic-wood composites contain some plastic components, it can it can also preventeating, making it a kind of excellent and very durable outdoor building materials, which can be used in all aspects of outdoor, can replace the wooden components used in ports, docks and so on, and can also be used for replacement. On behalf of wood to make a variety of packaging, pallets, warehouse mats and so on too numerous enumeration, very wide use. One of the most important uses of wood-plastic materials is to replace the use of solid wood in various fields, the most widely used in construction products, accounting for 75% of the total wood-plastic composite supplies. The main uses of wood-plastic composite materials are outdoor plastic wood floor, plastic wood box board, plastic wood decorative board, plastic wood sign board, plastic wood structure material, plastic wood hydrophilic floor, flower frame corridor, plastic wood terrace, simple plastic wood room, indoor, wall skirt, bathroom board, door and window frame cover, indoor partition, sound insulation board (wall), decorative lines, etc.

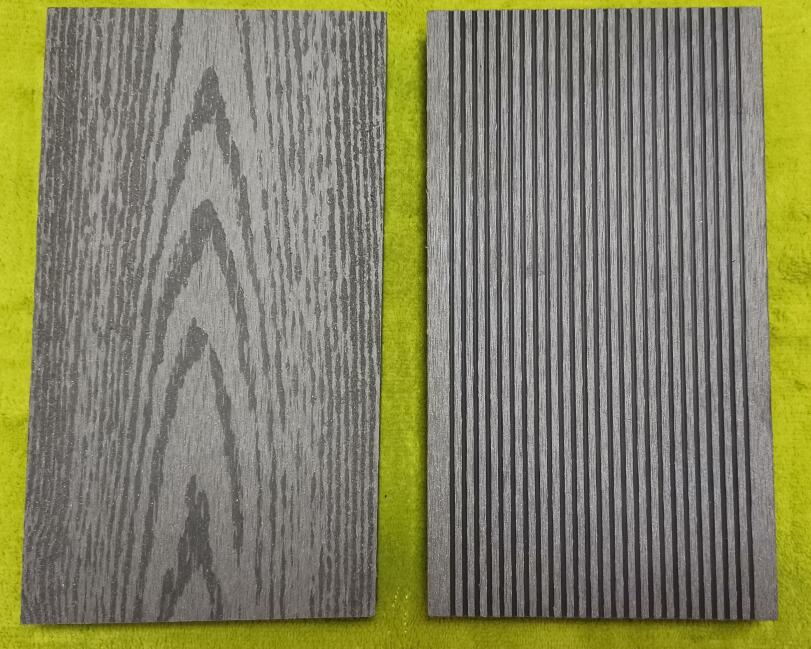

wood plastic composite decking in the performance of wood and plastic dual advantages, appearance and wood texture realistic natural and good material stability, not easy to crack, deformation, warping. Anti-aging products, anti-corrosion, anti-insect ants, water absorption is small. Rich in color, as easy as wood processing, whether cutting, planing, nail, drill are very simple. Furthermore, wood-plastic outdoor flooring is produced by high temperature melting and high pressure extrusion; therefore, wood-plastic flooring products have a more compact structure. As high as 1.3 g/cm3, the density of wood-plastic floors is about three times that of conventional wood, wood-plastic floors also have better anti-mildew, anti-corrosion, anti-moisture, insect control effect, but also has more wear resistance, stain resistance and better aging resistance.

Changxing Hanming Technology Co.,LTD

Contact Person: JEAN

Email: Jean@hanmingwpc.com