European standard Unti-UV wpc decking in China| China composite decking for Europe

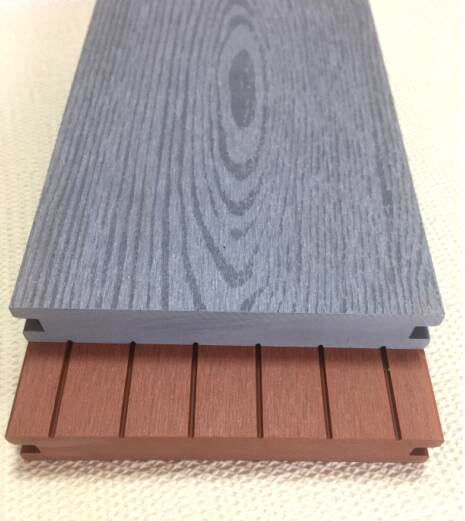

- Type:Plastic wood composite decking

- Place of Origin:Zhejiang, China (Mainland)

- Brand Name:HANMING WPC

- Technics:Wood-Plastic Composite Flooring

- Product name:European standard outdoor wpc decking

- Price: 16usd/sqm -22usd/sqm

- Material:HDPE+wood+additive

- Color:Grey, green, yellow,etc.

- Surface:Grooved, Sanded,wood texture

- Certificates:EN15534, ISO9001, ISO14001,ASTM

- Function:Weather Resistant, suitable from -40℃ to 60℃

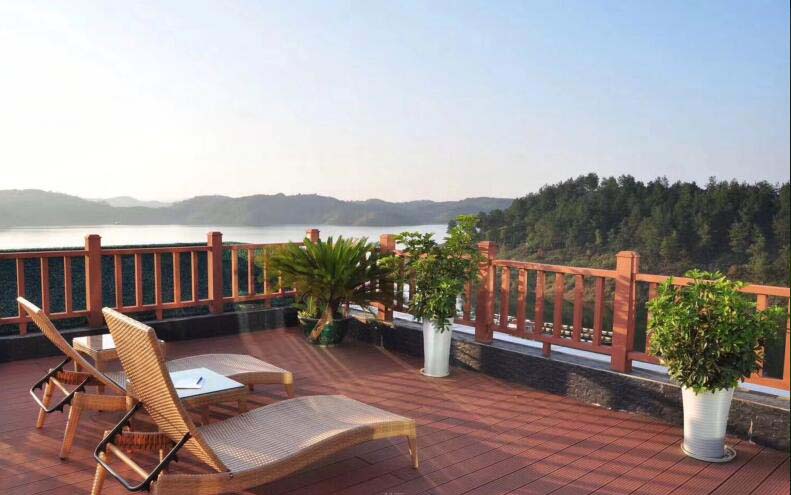

- Usage:Project, terrace

- warranty:10 years

- delivery time:1 20′ GP about 15 days

There are significant differences between China and Europe in the production standards of WPC Decking materials, which are mainly reflected in environmental protection requirements and durability testing. From an environmental perspective, European WPC products must not contain substances that are harmful to the human body or the environment.

Regarding durability testing, European standards usually include detailed tests on the UV resistance, water resistance and impact resistance of plastic wood Composite decking. For example, European standards require that WPC decking can maintain color stability and structural integrity after long-term ultraviolet exposure. At the same time, European tests will also simulate different climatic conditions and mechanical pressures to test the actual durability of WPC decking. In China, although there are also relevant durability test standards, the level of detail and coverage of the test methods may not be as comprehensive as in Europe.

Chinese WPC Decking produced in China and meeting European standards has occupied a place in the European building materials market with its excellent environmental performance, high durability and unique aesthetics.

These WPC decking products strictly control the emission of harmful substances during the production process, meet the strict requirements of Europe for environmentally friendly materials, ensure the safety and health of indoor air quality, and provide a greener and safer choice for homes and public places.

In terms of durability, they are specially treated to resist UV radiation, extreme weather conditions and daily wear and tear, significantly extending their service life. In addition, the design of these WPC deckings incorporates modern aesthetic concepts, not only reproducing the texture and color of natural wood, but also providing a variety of color and pattern options to meet the pursuit of individuality and aesthetic needs of different consumers.

This European standard WPC decking achieves a perfect combination of performance and beauty by optimizing the material ratio and adopting advanced manufacturing technology.They not only give people a warm and natural feeling visually, but also are not inferior to traditional solid wood materials in practical performance, and even show better performance in some aspects.

For example, these wpc deckings have better moisture resistance and corrosion resistance, and can maintain stable performance even in humid environments, greatly reducing maintenance costs and frequency. In summary, Chinese WPC decking that meets European standards is gradually becoming one of the ideal floor materials in the minds of domestic and foreign consumers with its environmental protection, durability and beauty.

Plastic wood composite decking Picture

If u are interested in our WPC Products, pls contact with me by mail : Admin@hanmingwpc.com

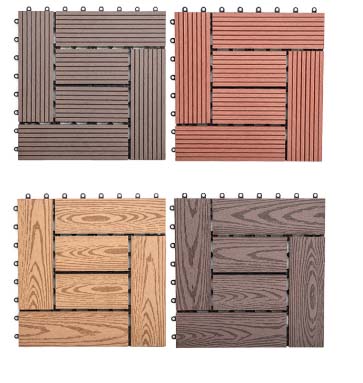

Other Products by plastic wood composite materials:

Plastic wood composite Bench

300x300x22mm interlocking composite flooring

Plastic wood composite Pergola

China’s labor costs are relatively low and its production efficiency is high, which makes Chinese WPC decking highly competitive in price.

As the world’s largest producer of wpc composite materials, China’s products are well-known for their price advantages, reliable quality and variety. The growing demand for environmentally friendly materials in the European market has created favorable conditions for the export of Chinese wood plastic flooring materials.

If you are in Europe or Other Countries , and want to Import the Composite decking from China, welcome send us your inquiry by email: