Plastic wood composite exterior wpc wall panels | Hanming WPC wall CLadding

Item No.: WPC panels wall

Brand : HANMING WPC

Material: WPC(Wood plastic composite)

Price: 11usd/sqm-15usd/sqm

Normal Size:200x22mm,156x21mm,140x21mm

Length: 2.2m, 2.9m,and 5.8m or customized

Accessories:clips + WPC joist + WPC skirting

WPC wall Panel is a new material wall board conceived with the development of wood plastic material in recent years, wood plastic wall Panel and wood plastic decking, are produced through the extruder, it is not easy to deform, moisture-proof, insect prevention ant, has a certain environmental protection performance.And it is beautiful and generous, there are a variety of colors for wall panel ,Instead of anti-corrosive wood material, mostly used for the three-dimensional effect of the wall.

Material of composite exterior wpc wall panels: 35%PE+55% Wood power+10% Additives.

Advantages of wpc exterior wall panels:

1, low loss: plastic wood wall Panel is a kind of building materials, there are many specifications of arbitrary choice, do not waste materials.

2, the surface does not need the paint treatment: many wood or other material surface will carry on the paint or the waterborne coating treatment, from this can see the plastic wood wall board construction is simpler, the maintenance is also simpler.

3. Service life: Ordinary wood can be used for 3-4 years, while plastic wood WPC wallboard can be used for 10-50 years according to foreign data.

4. Physics: anti-slip, wear-resistant, non-cracking, non-insect-eating; good strength, high hardness; low water absorption, good sound absorption effect, aging resistance, corrosion resistance; anti-static and ultraviolet ray, insulation, heat insulation, flame retardant; can resist 75 ℃ high temperature and -40 ℃ low temperature.

exterior wall panel made of wpc

The industrialization of plastic-wood materials originated from the United States in the 1980’s and was initially used as modified plastics. With the improvement of technology, wood-plastic has the advantages of plastic, wood, metal and so on, and has become a new material of its own system. At present, all kinds of wood-plastic products in the United States, Canada, Germany, Britain, the Netherlands, Japan and South Korea and other countries have been widely used, forming a more standardized industry and market.

Extensive application of plastic-wood materials

In the market, as people’s pursuit of healthy living and comfortable living environment is increasing, wpc composite exterior wall panels have been widely welcomed by consumers due to their formaldehyde-free and pollution-free characteristics. Unlike traditional building materials, it does not require complex maintenance, saving later maintenance costs and reducing the burden on the environment.

In practical applications, the diversity of wpc composite exterior wall panels is also one of the reasons for its popularity. Whether modern and simple, European classical, or oriental Zen, composite exterior wall panels can meet the needs of different styles of architecture with their rich colors and textures. It is easy to install, fast to construct, and can greatly shorten the construction cycle. This is undoubtedly a major advantage for the modern construction industry that pursues efficiency.

The promotion of every new thing is inseparable from the test of the market. Currently, composite exterior wall panels are still facing the challenges of relatively high prices and insufficient consumer awareness in the market. But as time goes by and technology advances, these problems will be solved. After all, for the construction industry that pursues long-term development, investing in environmentally friendly and sustainable building materials is a responsible choice for the future.

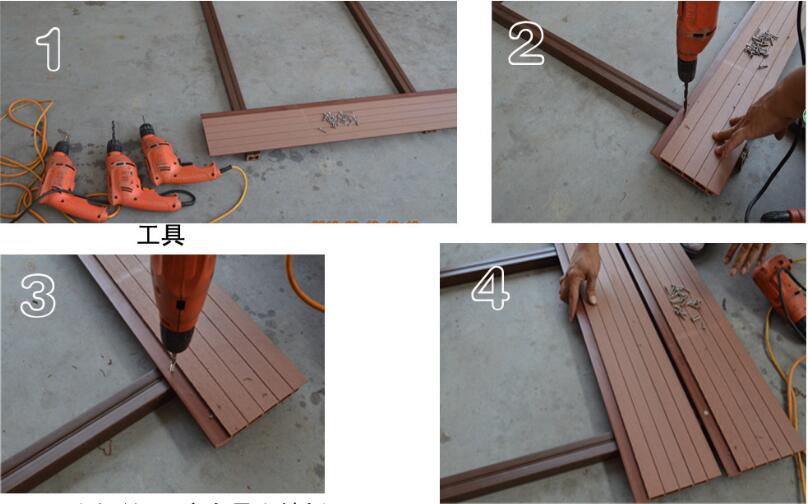

Installation procedure of WPC exterior wall panel

1: when installing the plastic wood exterior wall Panel, fix the plastic wood keel (or galvanized square tube) with the Expansion screws first.

Aslo the distance between the keels is generally not more than 30 cm;

2: use stainless steel buckle (or self-tapping screw) to fix the plastic wood wpc wall board on the keel.

3: when installing self-tapping screws, drill holes in the corresponding position and then tighten the self-tapping screws; at the same time,The diameter of the hole should be less than 3 / 4 of the diameter of the screw.

4: when connecting with stainless steel clasp, the rubber hammer should be used to gently tap the plastic wood exterior wall board,Ensure the uniformity of the gap and the beauty of the whole construction surface

5: after the completion of the construction, in the windows, corners and other places, can be used to cover the edge with WPC Side cover and make beautification, to prevent the external wall Panel Scratched.

Is the price of wood-plastic WPC exterior wall cladding expensive?

we think it is very economic for the Outdoor Project.

Project In Thailand

Client: Abbott

Country: Thailand

Mr. Abbott is a Bangkok expert in construction field and he has business in many countries. He first came to us for an villa wall Panels project. The House has metal structure, so he would not need joist.we gave him suggestion on the Wpc wall Panels style: HMW-018 and later sent him samples. He was satisfied with our product quality but he wanted the style with wood texture, which we didn’t send samples to. Acknowledging this, we quickly re-send him samples of this style. He was finally very satisfied with this wood texture .

For the Price, It is Only 14 USD/SQM , which is acceptable for that Projects. At last,Mr. Abbott Purchased one 20′ Container from us , He said will order another one from us Soon.

If you need exteior WPC hollow or Solid decking , aslo we have them.

If Any Question from you , Pls Send email to us: Admin@hanmingwpc.com

OR Click Here to send us a Inquiry.