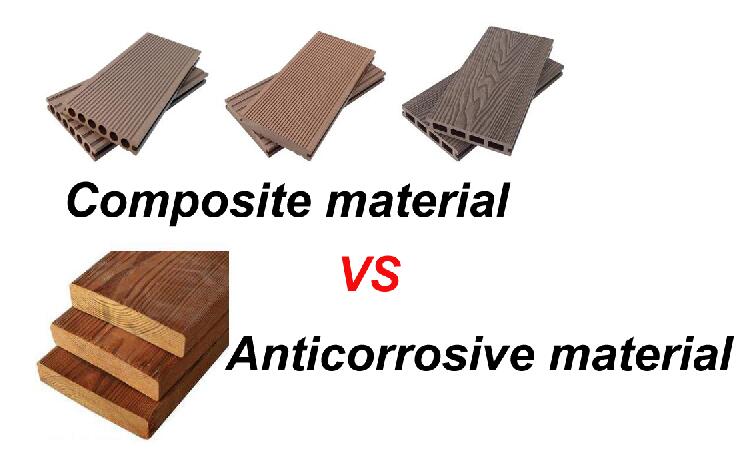

In recent years, plastic wood materials have been more and more favored by the majority of users. We can see the use of plastic wood everywhere in many places. So today, we’re here to give you the difference between wood-plastic materials and anticorrosive materials:

1. Plastic wood products can be maintenance-free. Preservative wood due to ambient temperature, humidity and solar ultraviolet radiation, generally in one year to do maintenance or paint. In the long run, the maintenance cost of WPC is far from anticorrosive wood products.

2, Wood plastic composite is a kind of profile, hollow specifications are many. A lot of materials have been saved. We all know that aluminum doors and windows can be popularized so quickly, is because it is hollow profile, if solid, then the price is incredibly high. wpc hollow savings part, although not as high as aluminum, but also relatively considerable. It is well known that hollow not only reduces weight, but also increases strength. Plastic wood can be hollow, but preservative wood is impossible.

The loss of plastic wood profile is less than that of anticorrosive wood. Under the same construction area or volume, the loss of plastic wood is less than that of anticorrosive wood. Because the plastic wood is a profile, according to the actual size of the landscape engineering needs, can produce the required length, width, thickness of materials. The length of the preservative wood is prescribed dead, usually 2 meters 3 meters and 4 meters.

Anticorrosive material

4, the WPC surface does not need to do the paint treatment. General anticorrosive wood construction or construction process to the wood surface paint or paint water-based paint.

5, WPC can be in the same construction conditions, can win more with less. Let me say, for example, that outdoor flooring is usually paved, and in the case of wood, it needs wood about the thickness of 45MM. Plastic wood, only need 25MM thickness of the material, its strength is higher than the 45MM anticorrosive wood. In other words, if the use of wood is 1 cubic meters, then plastic wood only need about 0.5 cubic meters.

6. The service life of plastic wood board can generally reach 8-9 times that of ordinary wood. Foreign data show that plastic wood can be used for 15-30 years.

7, the replacement of plastic wood products is that the removed plastic wood can be recycled and reused, reducing the consumption of resources, which is in line with the low carbon economy.

8. The anticorrosive wood is treated with the anticorrosive agent copper chromate (CCA), which is carcinogenic. Plastic wood products are non-toxic, non-carcinogenic, safe and environmentally friendly.

Contact Person: Nick Qian

Nick@hanmingwpc.com

Published on: Sep 1, 2018 15:06