WPC is made of a mixture of materials consisting of wood and recycled plastic. It has a nice appearance that resembles real wood and requires little maintenance, which makes it a great alternative to other types of decking.WPC is the abbreviation for wood plastic composite.

WPC decking is the fastest growing wood deck alternative on the market. It boasts low maintenance and a much longer lifespan than wood decking.

WPC decking is a man-made building product that includes an approximate equal mix of recycled wood fibers and recycled plastic.

Some deckings are Made of Bamboo Power + Plastic, if So, we call it BPC decking.

The composite decking color can be grey,Black,Brown,teak,etc. it can be used in balcony,swimming pool,outdoor flooring,Park,walk road,wharf,Garden,tourism place and So on.

WPC deck is made from wood power and plastic with some additives through an extruder at high temperature.

WPC DECKING EXTRUDER | Manufacturer in China

Many outdoor projects have replaced wooden boards, and many hollow and solid decking surfaces can be printed with wood grain, using hidden accessories and after installation, played a non-slip and close to natural effect.Due to unti-UV and antioxidant properties, WPC Decking has a long service life.

Hanming Provide Better Quality WPC decking and other composite materials in China.Better decking flooring means use good formula and Materials.Many projects in China also use our products.Hanming is A exporter of WPC board, WPC wall cladding, Composite Fencing, composite Railing,etc.

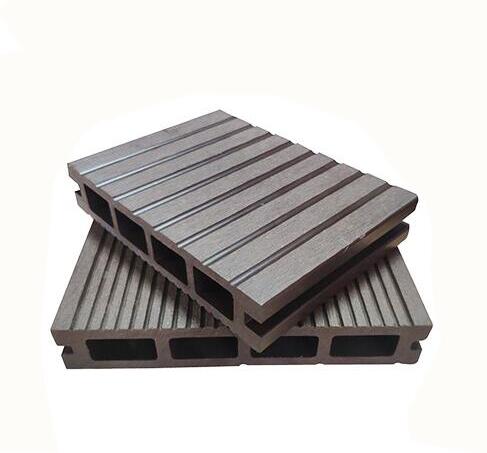

WPC decking Board

What is the formula of WPC decking or other WPC Products?

The formula of each factory is actually different, and the different formula also affects the price of the product, we think good WPC product must be added with a certain dose of antioxidants, anti-ultraviolet agents, etc., the general formula of our WPC DECKING we sell is 55% Wood Power +35%HDPE +10%Additives,.

The usual WPC Decking sizes are as follow:

138X23mm, 140X20mm, 140X25mm,140x40mm, 150X25mm, 146X22mm,146X31mm,etc.

After the WPC board is produced from the extruder, it generally needs to be polished, This make the plastic off the surface, and the factory will use a grinding machine to treat the opposite sides of each board, It should be pointed out here that the WPC joist does not make such a treatment.

Also, on the flat side of the wood-plastic decking, out of beauty or the pursuit of similar wood effects, The factory will generally press the wood grain on it, and the wood grain has the ordinary wood texture and 3D embossing texture points.

-

Below is a photo of ordinary wood texture being pressed

Advantages of the WPC decking:

Durability: Composite decking is designed for maximum durability. It resists fading, staining, scratching and mold, and won’t rot, crack or warp. It’s also insect-proof and splinter-free, making it safer and more comfortable for families with kids and pets. Especially for capped decking board.

Low-maintenance: With composite decking, you never need to worry about sanding, staining or painting. Just an occasional soap-and-water cleaning is all that’s needed to maintain stability and beauty for decades. Hanming decking even comes with a 5-year Fade and Stain Warranty, ensuring that it will continue to look and perform as well as the first day it was installed.

Sustainability: Composite decking provides the look and feel of wood without the environmental impact. The deck boards are made using recycled content, including reclaimed industrial wood scraps and recycled plastic from common items such as shopping bags and newspaper sleeves.

Hollow composite decking With 3D Embossing

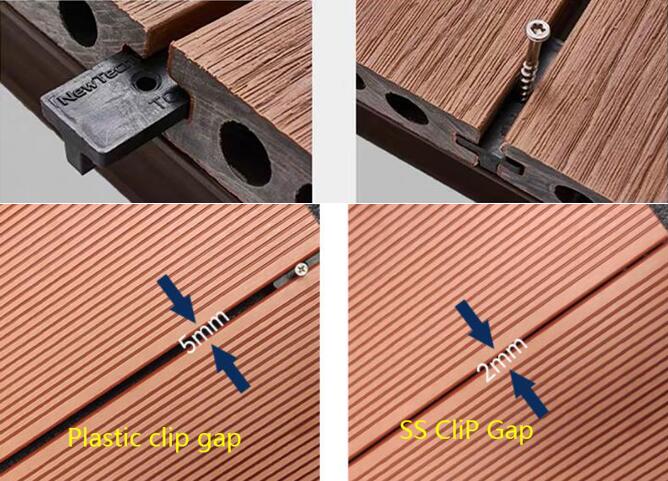

The following items are the accessories required for wood – plastic decking installation.

Many people ask what Capped WPC decking and interlocking WPC decking tiles are? What do they mean? Are they the same WPC decking?

Yes Capped WPC decking and interlocking WPC decking tiles are also WPC decking, but there are Some difference between them.

1:For capped composite decking,It is produced via a co-extrusion process where a 360 degree outer armour is used to protect the core of the deck from the elements. As a result to be color fade resistant, strength load resistant, stain resistant and also highly slip resistant.

Capped WPC decking protective layer: the protective layer of capped composite decking with special formula, create clear wood grain and natural color, at the same time four-sided coating, all-round protection plate, more wear-resistant, anti-scratch, anti-stain. In crowded areas, can effectively prevent people and hard objects caused by the scratch, more can withstand the nature of all kinds of bad test. The protective layer is produced at the same time as the plate and will not be separated.

Inquiry from us Get a complete quotation from hanming WPC Manufacturer

2: For interlocking WPC decking tiles, it is a combination of WPC board and plastic base, installation without the need of keel and screws, etc., only need to splice the installation can, the surface of the board has 72 X11mm,55X10mm, WPC boards placed in the plastic base fixed by screws, commonly used decking tiles there are300X300X22mm, 600X300X22mm,etc.Surfaces of the plate can be grooved, or with WOOD texture.

The difference between WPC Decking and anticorrosive wood:

1:The loss of composite profile is lower than that of anticorrosive wood:

Under the condition of equal construction area and volume, the loss of WPC is less than that of anticorrosive wood. because plastic wood is profile, according to the actual size needs of different indoor and outdoor projects, the length, width, thickness of the material produced in accordance with the need and the length of anticorrosive wood is specified dead, generally 2 meters,3 meters,4 meters.

2:Plastic wood is a kind of composite profile, many hollow specifications can Save a lot of materials;

Aluminum alloy doors and Windows can be so quick popularization is known to all, because is hollow profiles, if be solid, so the price is incredible high . Plastic wood hollow savings, although not as high as aluminum alloy, but also more objective. We all know that hollow can not only reduce weight, plastic wood can be hollow, and anticorrosive wood is impossible.

3:The WPC surface does not need to be painted

General anticorrosive wood construction finished or construction process should be painted on the wood surface or painted with water-based paint.

4:WPC products are maintenance-free

Anticorrosive wood due to ambient temperature and humidity and solar ultraviolet radiation, generally in one year need to do maintenance or paint. In the long run, the maintenance cost of plastic wood is far lower than that of anticorrosive wood products.

5:The dismantled wood plastic can also be recycled to reduce the consumption of resources, in line with the concept of environmental protection, low carbon and economic。

The production of WPC decking is made by extruders at high temperatures .material is made of wood powder, High density PE and additives.

What the application of wpc decking ?

As WPC decking is Versatile material, high performance, low maintenance, Wood-plastic floor has been widely used in many fields.It can be used for patio deck, Garden floor,pontoon, Park, Road floor, Swimming Pool decking board,Etc, and the Wood Plastic composite material is aslo Produced to be Railing, Post, Pergola, Pavilion, Bench, Fencing, Flower box and So on.

How About the Prices of the WPC decking from China ?

The price of WPC decking is slightly more expensive than wood floor.But because the wood-plastic floor is maintenance-free, In a few years, coupled with maintenance costs, the price of wooden floors may exceed WPC decking.So WPC deck is a popular product now and in Future.

WPC decking is mainly used for outdoor decoration.You can see it in parks, balconies and other Places.Nowadays, the price of composite wood decking from every manufacturer on the market is different, the price between each profile is different too.The common price of wpc decking is about 15-30USD/㎡.For those Co-extrusion decking, the price will be a little higher.If the paving area is large, the Suppliers will aslo give some discounts.

Why wpc decking is health and Environmental protection material:

On raw material, WPC Decking is mainly composed of recycled plastic, wood fiber and a small

amount of processing additives.during the production process, it is made by the molding

equipment and heating extrusion after mixing.WPC do not contain toxic substances, dangerous

chemicals, preservatives, etc. WPC Decking can be recycled, reprocessed and biodegradable.

In use, WPC Decking has the secondary processing properties similar to wood, which can be

cut, glued and fixed with nails or bolts. also do not need to use the paint on the late maintenance,

just clean it with water and keep it like new for a long time.

Hanming WPC Provide the High Quality WPC decking boards from China, if you are interested in the WPC Products from China, you can send inquiry to us by email:

Our Email Address is : Nick@hanmingwpc.com

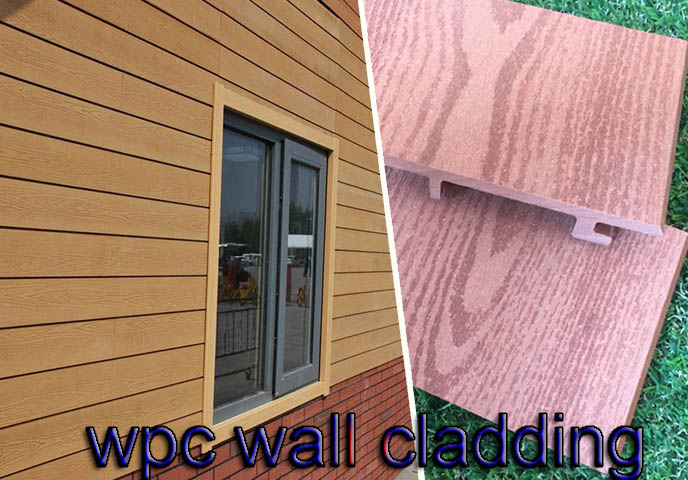

Other WPC products from us :

WPC Fencing——-composite fence panels

WPC Pergola

WPC Wall cladding for villa,House, School wall,etc.

Some questions which customers concern.

1.Does WPC decking or WPC product Fade color ?

The raw material of WPC Products contains anti-ultraviolet agent and weather resistant pigments. During the initial period, The color will fade slightly,but it will tend towards stability within a few weeks, after then the color will be natural and harmony with the environment.

2:Is composite Decking difficult to be installed ?

Composite decking can be easily installed,but you have to know something about the installation process.We have a page on how to install the outdoor decking, you can view the follow links.

How to Install outdoor composite decking ?| Tutorial guide for WPC decking installation

3.Why the keel is neceary for the intallation?

When we install the flooring, firstly the keels are fixed on the ground surface and then we put the Hollow or solid decking board on the keels. You know the wpc decking board can’t be put on the ground surface directly. For one thing, it can affect of the planeness of the flooring surface after installation. For the other thing, it is not good to control the drainage of the bottom, because the wpc decking board is mainly used for outdoor, which rains a lot. So keels must be used to hold the solid decking board when installed.

The author: Nick Published on: Jun 18, 2019 10:21